Introducing

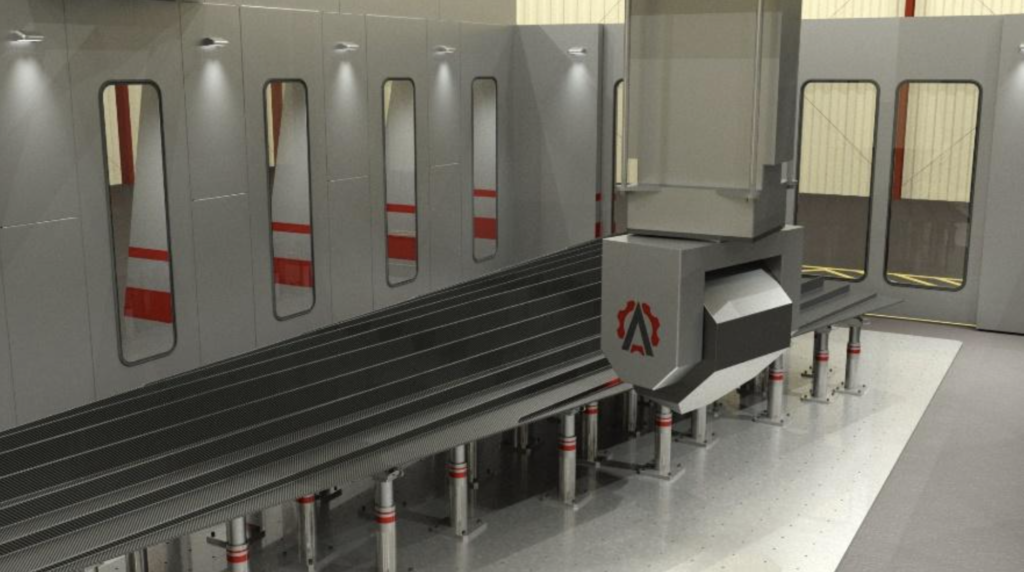

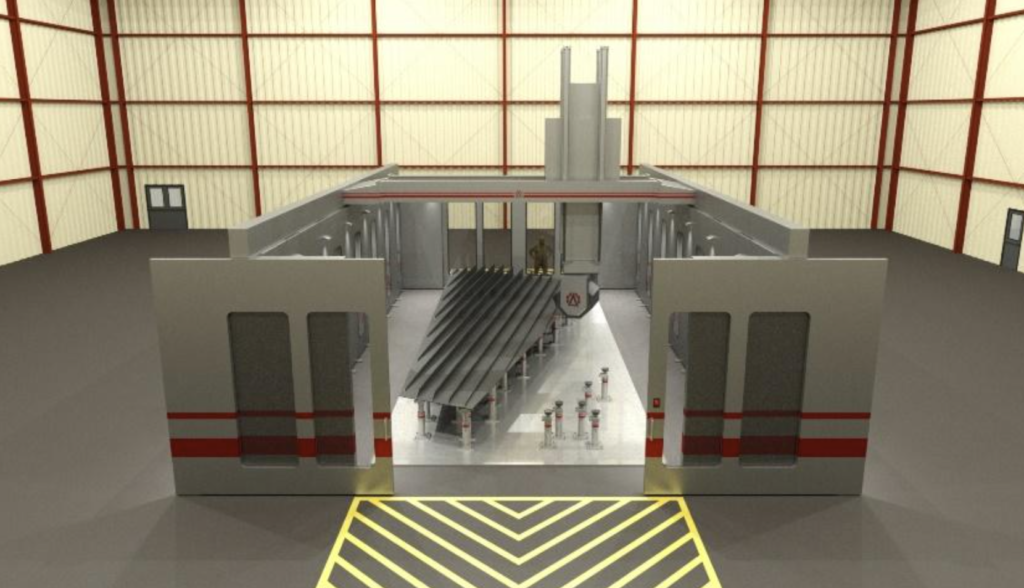

The world’s most accurate large-scale flexible manufacturing system.

The next generation of precision positioning systems.

Featuring our Motion Platform & Guide Drive System.

Industry Leading Features

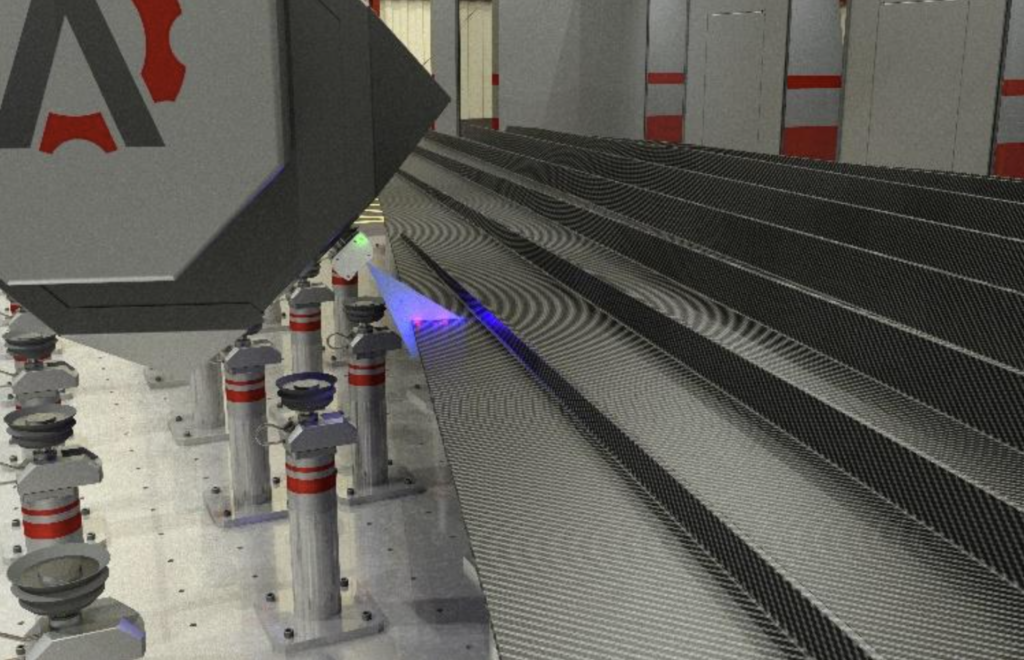

Unmatched volumetric accuracy

Zero backlash

Repeatable & correctable compensation on all axis

Micron accuracy

Patent-pending drive system for extreme precision

6-Axis head with interchangeable attachments

Easy Installation

Precise Positioning

Our precision comes from smart design features and technology, rather than extensive machining and overbuilding. This makes our system more adaptable, easier to implement, and more usable than existing systems.

Reliable

The precision of the AccuCell6 comes from a design and components that have repeatable performance, and then coupling those parts with a controller that can compensate for any variations on the fly. Recalibrating the machine becomes a very easy process and does not require any expensive machining.

Adaptive

Adaptive Manufacturing: Making Precision Parts from Imperfect Stock Materials

Inspect – Adapt – Machine – Assemble

Efficient

AccuCell6 relies on technology, rather than machined bulk steel, to give us our precision. By eliminating thousands of pounds of steel needed for other precision gantry systems, we have made our system more efficient to install and operate. Gone are the days of complex and massive foundation systems to support a precision gantry – AccuCell6 can be installed with very minimal foundation requirements. And because AccuCell6 is performing its work without moving so much steel, our utility requirements are also much lower than comparable systems.

Industries

AEROSPACE

DEFENSE

AUTOMOTIVE / EV

MARINE

Applications

INSPECTION

MILLING

DRILLING

WATERJET

Copyright © 2022, Advanced Machine Works, LLC. All Rights Reserved.